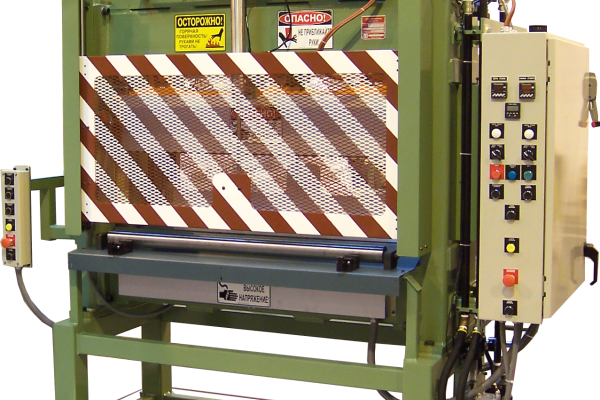

A Splice Press joins the trailing wire ends of a completed creel run to the starting ends of a freshly loaded creel. Splicing is accomplished by bonding the wire ends to uncured rubber strips by pressing the rubber/cord assembly between the electrically heated platens. RJS Corporation offers two types of splice presses:

1. Model 448

The Model 448 Splice Press is open on one end which allows the splice press to be moved onto or off centerline of the calender while the steel cords are in place. The press is mounted on tracks and motorized for ergonomic movement.

2. Model 344

The Model 344 Splice Press is fixed to the centerline of the calender window allowing the steel cords to freely pass through during a creel run.